| Construction |  |

||

|

I guess I just don't like to leave well-enough alone. But what's a hobby for, if not for fiddling? I've got to do something during through those long winter months, when rain keeps me from launching rockets in Northern California. So I sit in my rocket lab, with my space heater on, and sketch, and dream. And then I build! |

||

|

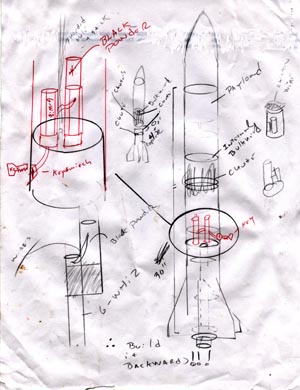

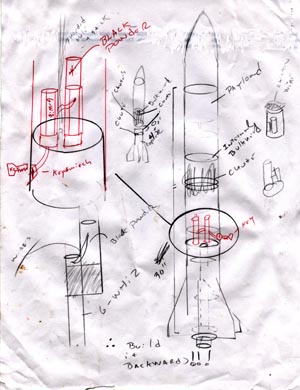

After flying at Blackrock for six years, I have learned that goopiness and strength will always beat prettiness and structural weakness. When in doubt, slather on more epoxy and fiberglass cloth. If the rocket is a little lumpy, so what? I've had many rockets make successful flights, only to crumple when they plow into the hard-pan playa. Plenty of fiberglass cloth and epoxy prevent this sort of disaster. I've had other rockets shred in mid-air because the large motors tear out of the airframe or create weird pressure effects that blow the airframe apart. Again, epoxy and fiberglass prevent this nasty mess. I am usually not one to fill the seam in the tube, having learned that the brute force of a motor rarely cares about a small indentation, while endless sanding can weaken vital components. Don't get me wrong: I sand a goodly amount, but I only grind out the biggest lumps of fiberglass cloth, using my Dremel tool. I've learned to leave well-enough alone and ignore the cosmetic lumps. When grinding a fin's edge, I always sharpen the leading edge and almost never sand the trailing edge. Sanding the trailing edge can weaken the fin. If a fin gets a knick or a busted end, I use Smith Fill Epoxy to replace the bunged bit--and many times, this ends up being stronger than the original fin. On rockets that do not use U-bolt shockcord mounts, I use Kevlar cord mounted through a body-tube slit (the very first way Estes mounted cords), sealed with epoxy. The combination of epoxy and Kevlar have made this a never-fail mount. But I still have problems with the shockcords themselves; the cords break rather frequently because of the stress during highpower ejection charges and because of the buildup of black powder residue, which seems to decompose a previously used cord's fabric. I plan on changing materials to avoid the cord breakage: nylon, Kevlar, and bigger bungies should reduce shockcord failure. I recently had great success using a fifteen-foot, 1/2-inch bungie shockcord in my NovaStar. Of course, the tube is one of the most significant parts of the rocket, and I spend a good deal of time fussing about tubing. Although Quantum tubing looks good and has no seams to fill, it builds a heavy rocket, and I've had one spectacular meltdown when using Quantum tubing. (To be fair, the meltdown was caused by a defective I-motor, not by the tubing.) I've had good success in using Rocketdyne's Virgin Craft Paper Tubes (no glassine), painted or dipped twice in Smith Liquid Boating epoxy. I use the boating epoxy because it is competitively priced and comes in larger containers, so I'm not always having to run out to the store to get more. I found the company when I lived near a marina. I like to use OSH hardware--swivels, snaps, and quick links--because it is cheap and readily available, although they don't always carry the smallest sizes. So, as summer 2000 comes to a close, what am I dreaming of for next year? Call it a Level 2.5 project: a two-stage Rocketdyne NorthStar K-1050 to K-250. I am concerned about recovering the sustainer and am considering getting a beacon of some type, after consulting with Cathryn Mataga, my ham radio operator friend. I don't know when I will fly the rocket: LDRS-20 will take place in the Mojave Desert during July 2001, and Balls will take place in the Blackrock Desert during September 2001--so if I want thirteen months (as of this writing) to build the beast, I'll need to fly it at the September launch. (See Two-Stage Rocket for an update on the completed project.)

All my construction projects are overseen by my rocket familiar: a mackerel tabby cat. As I was grinding my Quantum Leap a couple of years ago, the tabby wandered into my rocket lab. I shooed him out the door, but he kept coming back. He watched me every day as I built rockets, and eventually wormed his way into my heart. He started sleeping in the garage at night, and a year later, when he was wounded in a cat fight, my wife dragged him to the vet and let him become our second house cat. His name is Mr. Green (he's got green eyes), and I've named two rockets after him so far: a Rocketdyne Aries and a Rocketdyne NovaStar. |